What is a Die-cut Box?

Die-cut Box is a cardboard box made with custom and complex cuts to achieve a particular design.

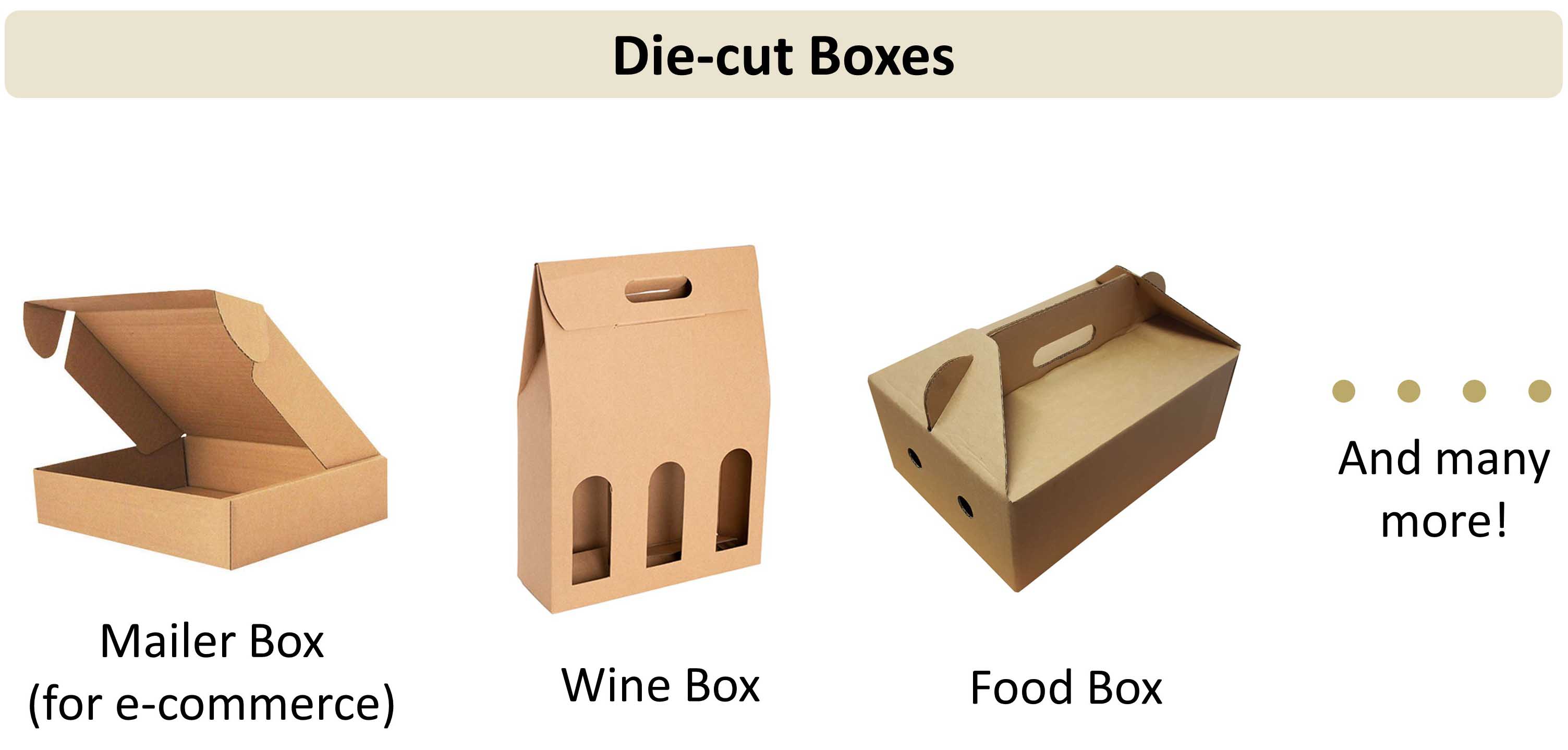

If a customer wants a custom box for his growing e-commerce business, he is looking for a mailer die-cut box.

If a customer wants a custom box to package his wine, he is looking for a wine die-cut box.

The applications of die-cut boxes are wide due and depend on the amount of customisation needed.

Why is it called Die-cut Box?

The Die-Cut Box, akin to its relative among corrugated boxes, the Slotted Container, bears its name from the machine responsible for its creation: the Die-cutter.

The machine allows more complex and unusual cuts to the box making the box much more customisable to particular needs.

Due to its greater customisability, there are many applications it can be used for, such as a wine die-cut box, food die-cut box, mailer die-cut box for e-commerce and much more.

Features of a Die-cut Box

Die-cutting finds extensive application in various industries, notably in e-commerce, where companies strive to have their boxes of a distinct identity. One notable advantage is that these boxes often require no tape for assembly.

A distinctive feature of a Die-cut Box is its angular, circular and sometimes unusual cuts. This can be seen from the illustration below.

Die-cut boxes also have special features such as hand holes which are common in document boxes.

How are Die-Cut Boxes manufactured?

The process involves mounting box blanks onto a wooden frame, which is then rotated in a circular and continuous motion. During this motion, precise cuts and creases are introduced, and the Die-cut Box is brought to life.

It's important to note that Die-Cut Boxes tend to be pricier compared to the standard RSC Boxes, primarily due to their intricate and more complex cuts.

You may watch the short 1-minute video below to gain a clearer understanding of the Die-Cut manufacturing process.

In short, what’s good about the Die-cut Box is its remarkable customisation potential which is made possible by the Die-cutter machine’s ability to incorporate complicated cuts, tailoring each box to its intended purpose.